Life at QCS

2025: What a Year for QCS Staffing!

IT

Choosing the Right IT Recruitment Agency in 2026

Life at QCS

Celebrating 10 Years with Louie Gibbons

Career advice

What is a Rigger and How Do I Become One?

Life at QCS

Introducing Our New Website: A Smarter, Seamless Experience for Candidates and Clients

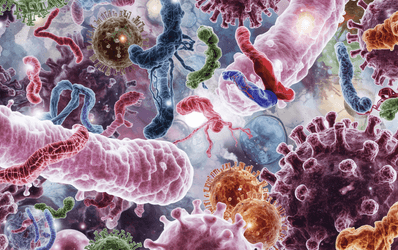

Industry insights

CapEx Hiring Lessons: How to Staff Biotech Start-Ups for Success in the US

Data Centres

Why Data Centres Are the Backbone of the Digital Economy

View all insights